Requirements for production optimization are complex and include many factors such as: load leveling, order prioritization, bottleneck operations, stock constraints, cycle times synchronization and many more.

Our solution enables the rapid creation of a dynamic Simulation Digital Twin of your plant and your supply chain and takes into account all those production requirements. You can virtually simulate an unlimited number of what-if scenarios and compare the options to support your KPIs. Thanks to the Cosmo Tech optimization algorithm, our solution can find the optimal plan to answer all of these scenarios.

The Cosmo Tech Supply Chain software solution is designed to:

- Recommend the best possible factory and production line configurations

- Determine optimal resources for production according to a set of rules

- Define an optimized production sequence robust to unexpected events

- Find new production tactics to rapidly react to production hazards

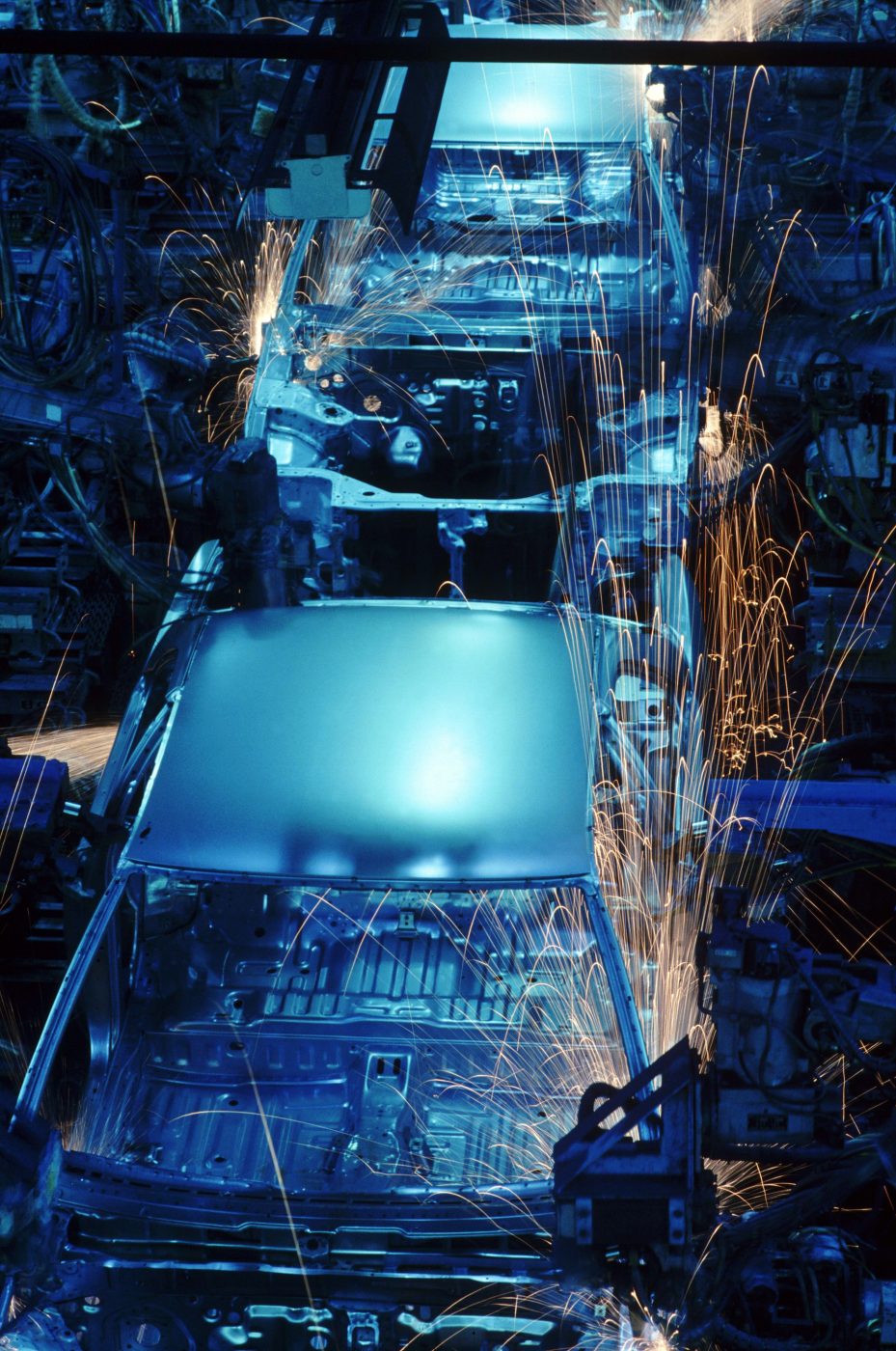

![[Video] Traditional vs Resilient Supply Chain Planning: Which side are you on?](jpg/adobestock_101964830-350x350.jpg)