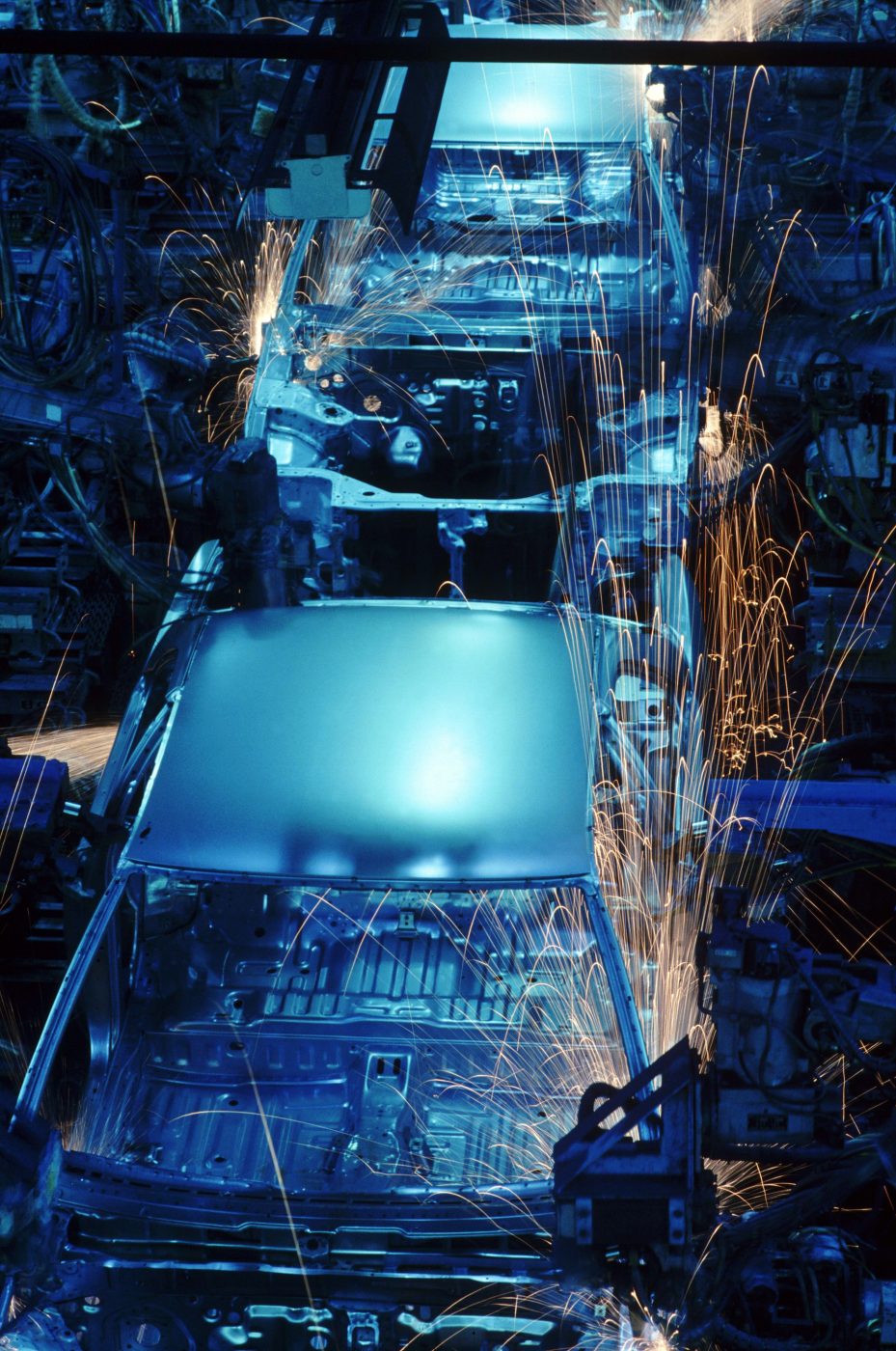

Uncertainty is a characteristic of the global business landscape in which supply chains operate. Market volatility and complexity don’t just create problems at a specific point in the supply chain, instead the impact can ripple throughout the entire system.

Compounding these with the past two years’ coronavirus pandemic and the ensuing adverse factors that have created new levels of supply chain disruption, businesses in all industries have been struggling to secure their market shares and margins. These challenges are new in many respects, so past experience cannot be relied upon to generate solutions.

Successful manufacturers use Cosmo Tech AI-Simulation Platform to:

- Ensure end-to-end visibility into the entire value chain

- Support and improve the decision-making process through optimal risk analysis

- Quickly respond to unexpected events before they create delays, production downtime and other bottlenecks

- Gain operational excellence and flexibility with rich flow and stock management rules

- Limit wastage by making the best use of available resources

- Find the optimal executable action plan to meet financial, operational and sustainability goals