Leave the guesswork behind!

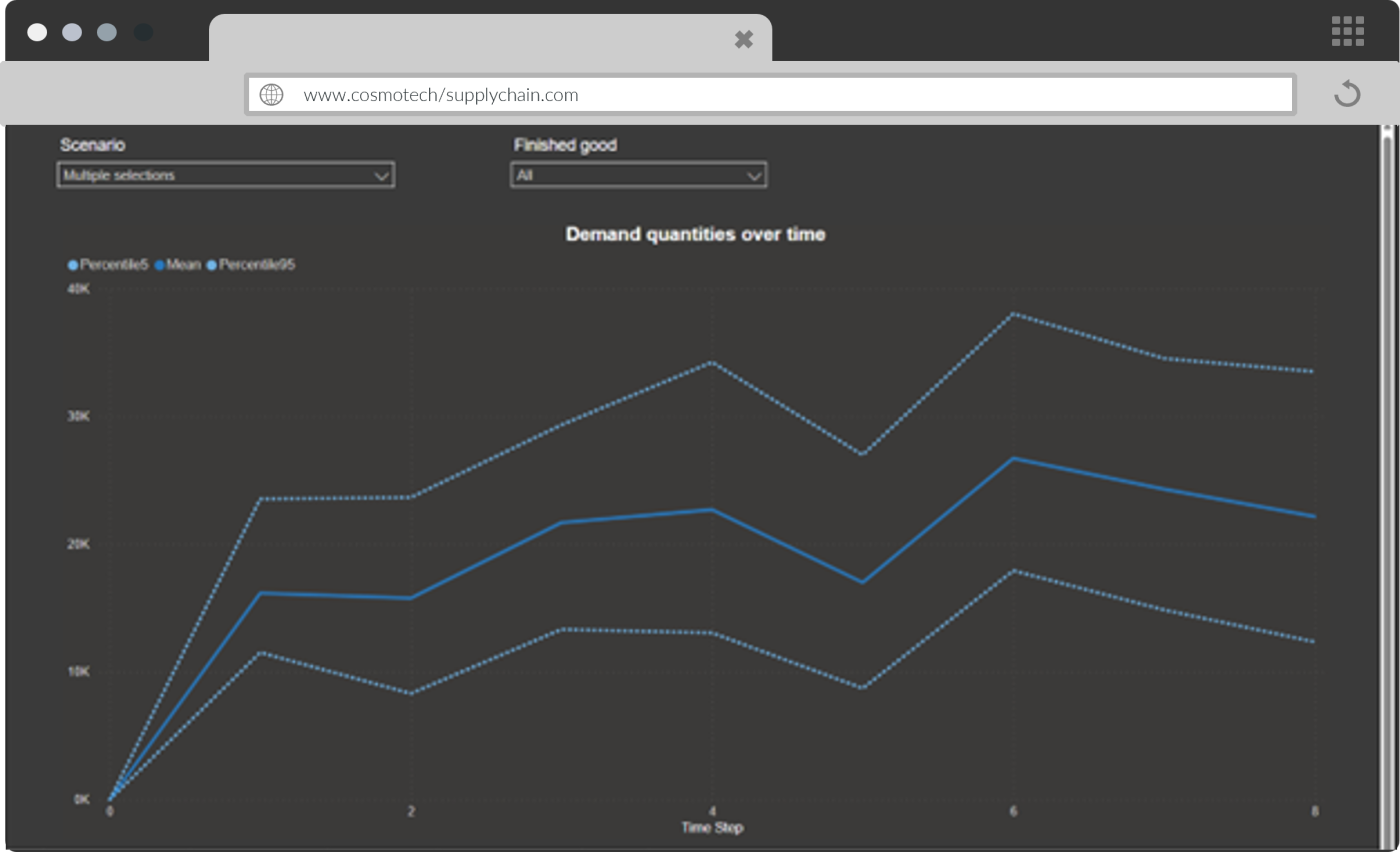

Forecasts based solely on historical data are merely guesses if they fail to consider various uncertainties.

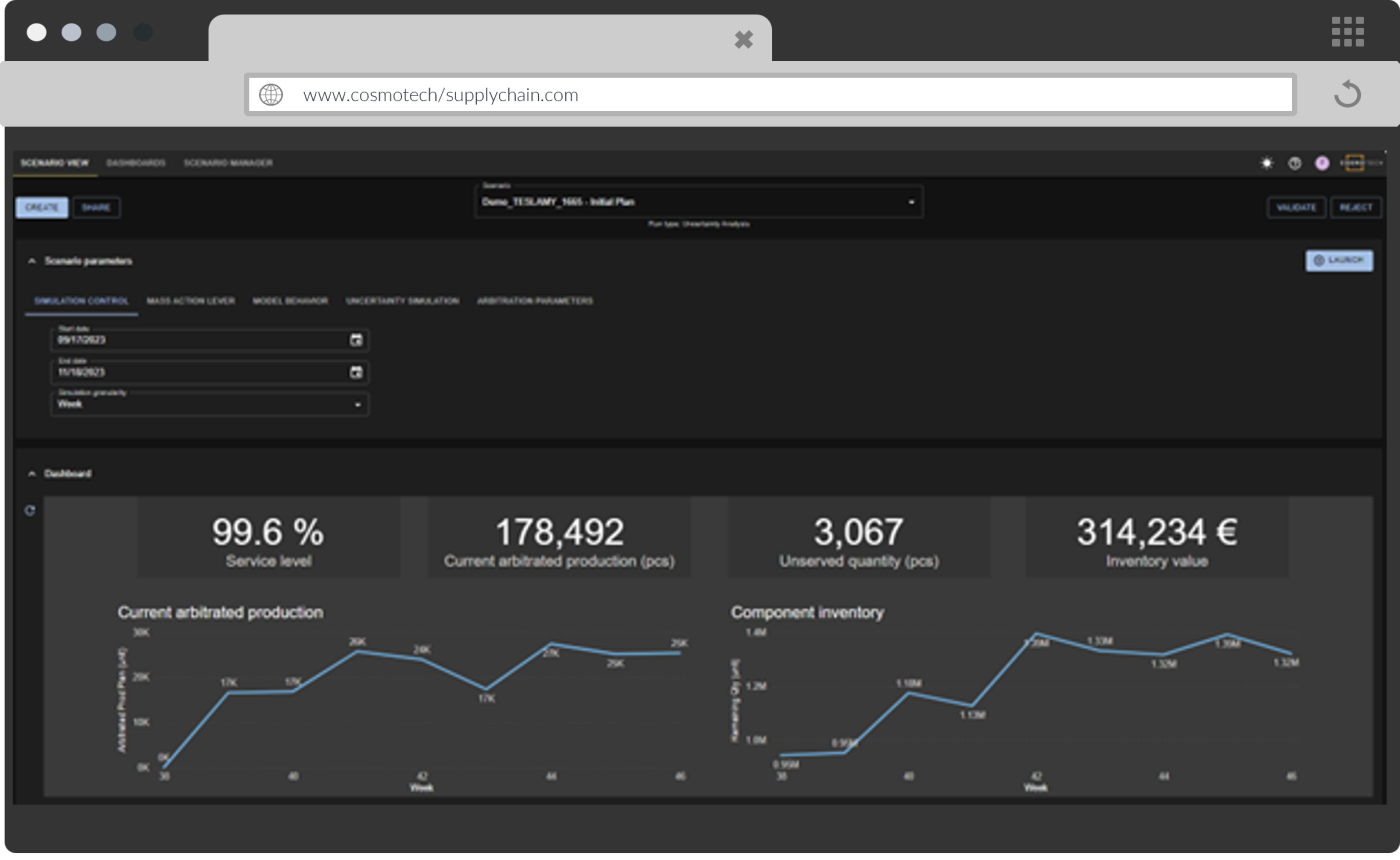

- Attain accurate, rapid results with AI-Simulation technology, ideal for industries requiring meticulous accuracy.

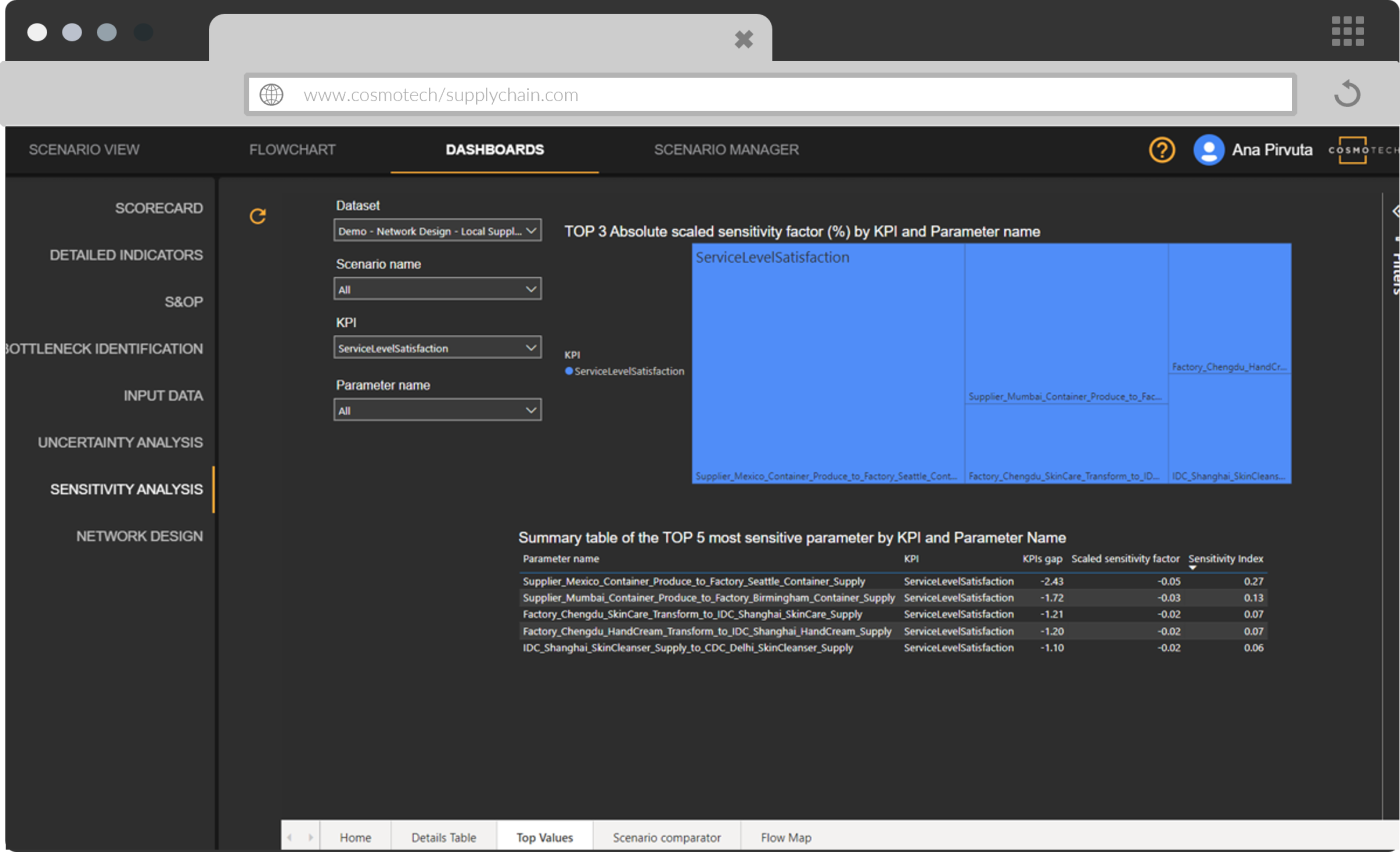

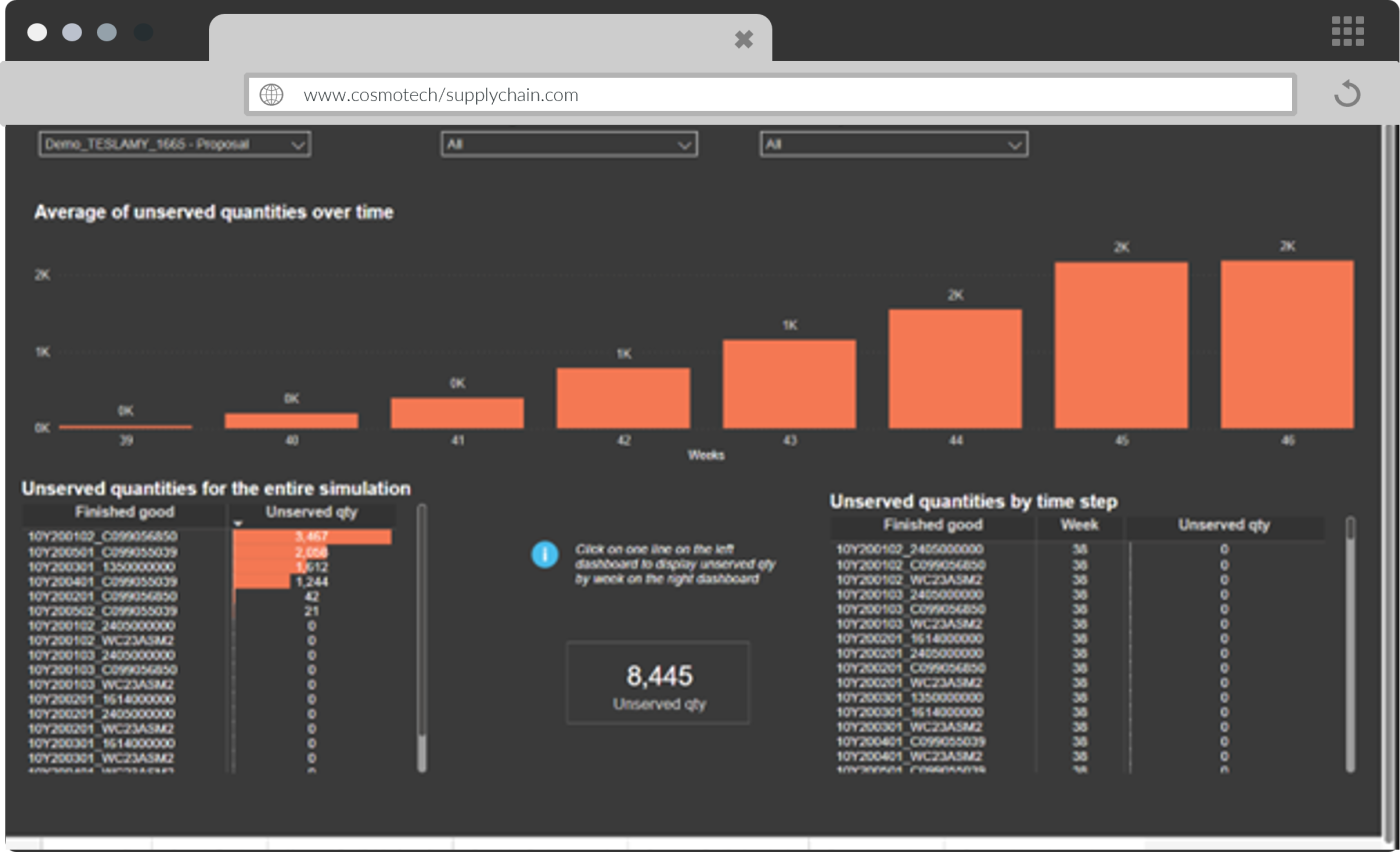

- Optimize supply chain decisions with a complete view of all potential outcomes and an understanding of how uncertainties affect key performance indicators, including service and inventory levels.

![[eBook] Tackling supply chain challenges with AI Simulation](png/sc-e-book-3-350x350.png)