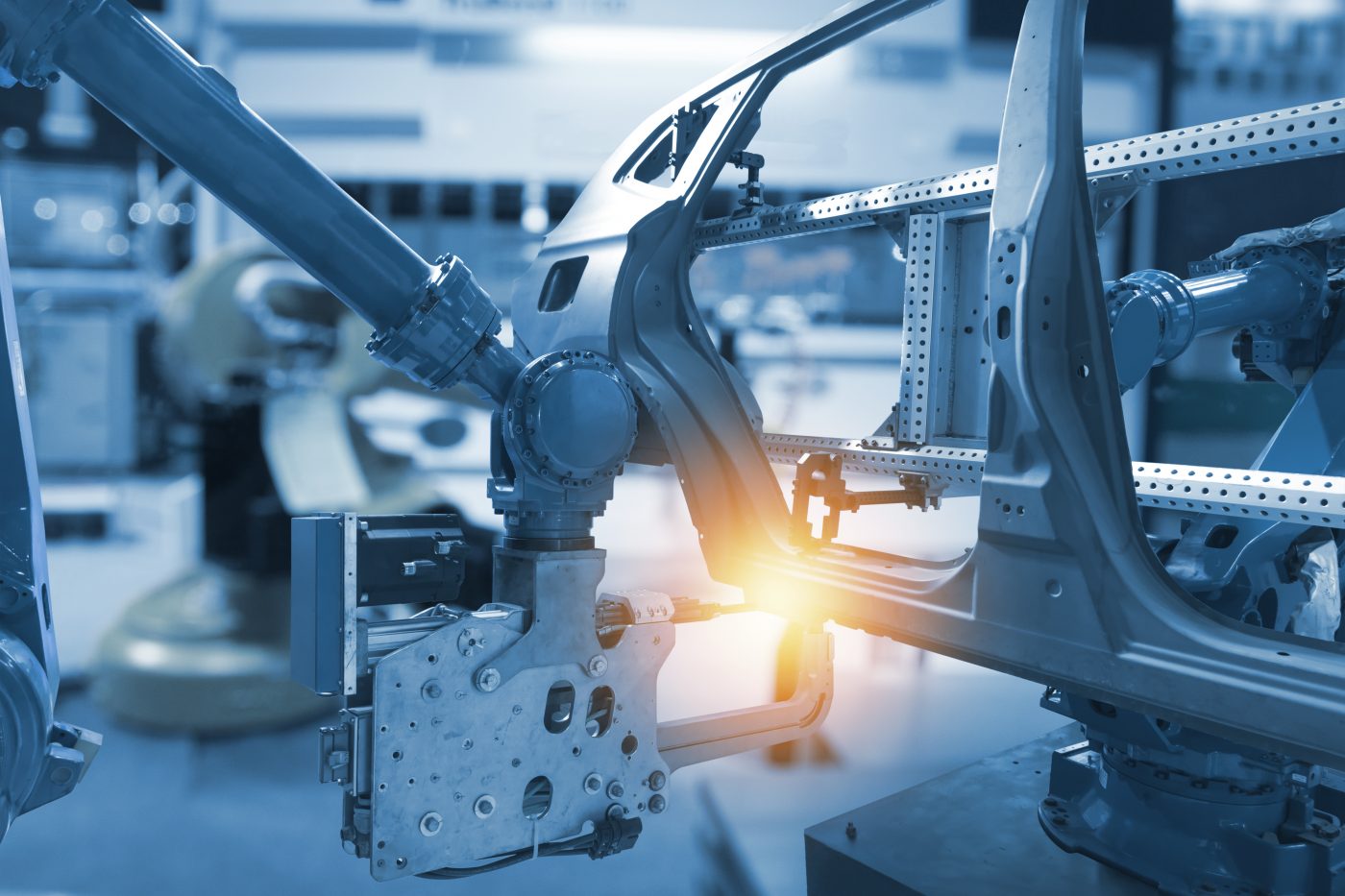

- Manufacturing

- Case Study

Speed up modification implementation process

Value creation

⇧

Increase Annual Savings

⇧

Increase modification processes efficiency

⇧

Anticipate resource bottlenecks

Increase Annual Savings

Increase modification processes efficiency

Anticipate resource bottlenecks

Our client is an international car manufacturer evolving in a very competitive market, where there is a downward demand with an aggressive price competition and strong pressure on production costs. They need to reduce production costs as much as possible by choosing new materials for their car production.

There are many changes to implement in car production comprised of numerous tasks, from models to design, technology and process point of views. The goal is to ensure that the modifications will be implemented as soon as possible in order to maximize cost savings on production, without disturbing other on-going activities.

They needed to have a solution that could help them implement these modifications in addition to their current planning, taking into account their constraints, anticipate bottlenecks & cascading effects.

With Cosmo Tech Plan, they created a Prescriptive Simulation Twin of their planning. This process included considering different constraints such as:

Cosmo Tech Plan supports you in designing a realistic, reliable and manageable plan in a highly constraining field requiring the execution of numerous interdependent tasks.

By re-prioritizing certain tasks, the production planning manager was able to save production costs by 8% while implementing the new modification on time, but not all modifications already planned. By subcontracting certain tasks for the testing phase, it will allow him to respect all initially defined deadlines and achieve 9% cost savings.

As a result, our customer found that the optimal solution was to subcontract testing phase for this implementation of the modification, because it will allow him to respect deadlines and achieve the best objectives in terms of cost savings on production.

With Cosmo Tech Plan, our production planning manager was able to: