The Route to Holistic Value Creation

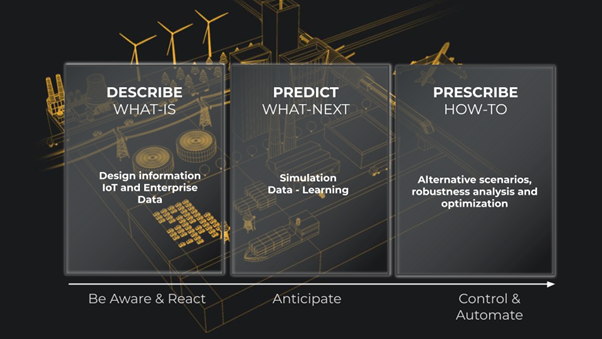

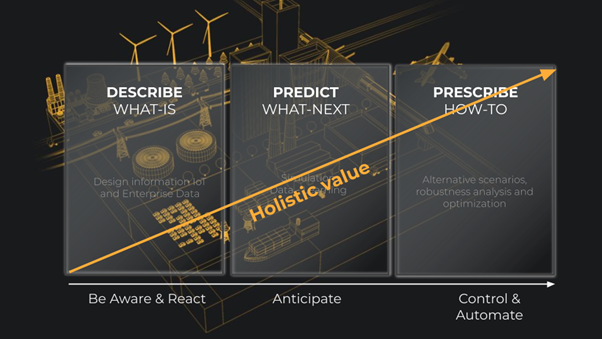

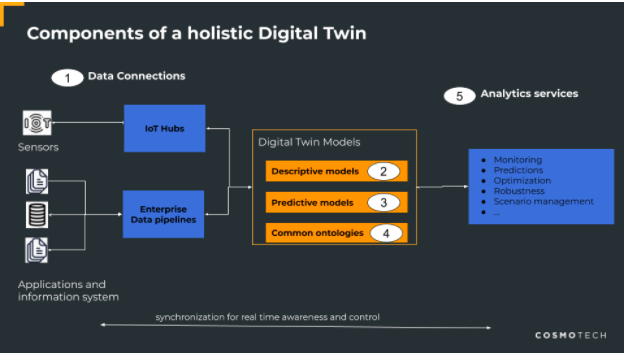

Understanding what exists and what is happening. Digital twins enable companies to accurately report on what exists, how it was built and commissioned, and monitor operational performance in real time from a single asset or process up to the level of the whole organization including all assets, processes, human capital as well as any environment factors to which they are connected.

Three technological approaches allow better awareness:

- Assets and system information management, such as BIM (Building Information Modeling), allows the capture of the design of the system, in order to share a common understanding to align stakeholders on what is built at the present moment, how it has been built, and what are the expected operational performances.

- IoT sensors integrated with digital twins allow efficient monitoring of machinery, assets, products, stocks, and other resources, giving a clear and accurate understanding of what is happening now. Additionally, historical operational data, provided in time series, delivers insights into what has happened in the past, with the possible combination of design data, to explain the current situation and detect anomalies. IoT can be deployed at scale on the physical system.

- Enterprise data, such as processes, sales, finances, resources as well as transaction data, can be leveraged to provide a consistent view and model on the organization’s resources, at many levels.

From a single asset or process to an entire system, digital twins can offer at this stage, through the descriptive modeling of components as well as the interconnections of environments, a holistic representation of what is built as wells as the monitoring of performance of the company at the present moment, connected to its environment, and explaining the current situation with historical design and operational data.

Understanding what will happen. Building from the first level of insight generated by system monitoring, additional value can be provided to organizations by predicting how the system will evolve, and what is likely to happen in the future. Here digital twins offer two major possibilities for organizations:

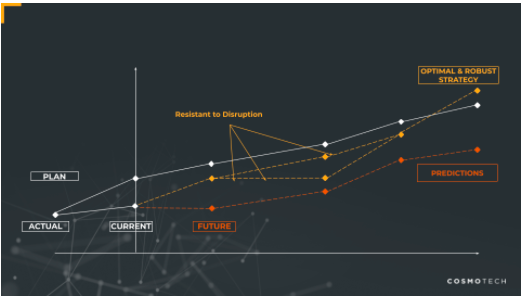

- Learning and extrapolating from historical data is effective to know what will happen in the future for common situations that have been observed in the past. Predictions about the future state of the system are made based on correlations and trends in the gathered data about assets and processes within the system.

- Simulation of the system is especially effective for cases where there is significant complexity in the system and for uncommon situations. The greater the diversity, interdependence, and interconnection in a system, the more likely simulation will be required to interpret the impact of system-level events on individual processes and sub-systems, and vice-versa. Under conditions that have never or only occurred infrequently before, and for extended timeline predictions in the future, simulation based on the dynamic behavior of the organization allows for the detection of emerging behaviors, predicting scenarios that have not happened before, and forecasting long-term results with greater reliability.

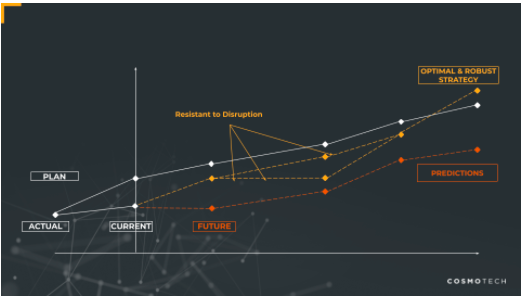

This level extends holistic understanding into the future and assesses the gap between what has been planned and how it will evolve. In both cases, predictions can be performed in real-time and provide insights to decision-makers ahead of any critical point.

Understanding how to act and control performance. Once an organization has the capacity to understand the current and future state of their system via their digital twin, they can begin to assess the robustness of their plans to uncertainty, test alternative plans via simulation scenarios, and optimize their performance. The digital twin represents the virtual environment for such experimentation by combining monitoring and predictive capacity with scenario testing, sensitivity analysis, robustness testing, and optimization technologies.

Uncertainties can be included in the model and the most influential variables can be identified to optimize alternative scenarios for planning resilience, and ultimately, automatically identify the most robust strategy or operational response.

Digital twins offer the capacity to virtually test levers that might be impossible to test in the field. Strategies and scenarios can be simulated to discover their impact on the organization before choosing which to implement, risk can be measured, safety levels optimized, and the impact of major transitions (decarbonization) or disruptions (pandemic disease impacts) assessed.

This holistic understanding, and the resulting value creation, therefore, impact the industry in a variety of ways.

At a micro level, for example, an organization can understand how a bottleneck in a production plant impacts other processes in the plant, learn why that bottleneck occurs, and identify the right lever to avoid it altogether. An organization might gain insights on how a shift from one strategic supplier to another impacts their delivery times or service levels, or how maintenance on a certain class of assets impacts the global manufacturing output of a single factory or group of factories.

At a macro level, the holistic understanding that a digital twin delivers can help in the strategic allocation of resources and the deployment of teams across an organization. Decision-makers can leverage the power of their holistic digital twin to generate robust and resilient plans that are truly systemic and not just global. What is more, they can safely automate processes and systems by training their automation algorithms to react to all possible situations and not only those that have occurred in the past.